The Murphy bed from Wallbed Systems

Highest Quality

Wide Range

Competitive Prices

The Murphy bed: A classic fold-down wallbed

The Murphy bed mechanism is the most proven of all wallbed designs, having been in use for many decades....for good reason. It is simple rugged and inexpensive.

This design will provide years of trouble-free use and operate for thousands of cycles. Our mechanism is constructed of high-quality steel and is then powder-coated with a scratch proof, black ridge or anthracite finish.

The counter-balance extension springs are made of our special alloy steel. The number of springs you use may be increased or decreased depending on the weight of the mattress and other bedding. We provide a full set of springs to balance all mattresses. A nylon webbing strap holds the mattress in position at all times.

The Murphy bed installation may be attached to the floor; alternatively we have developed a new Wall Mount Bracket to enable the installer to mount directly to the baseboard (skirting board) and not have to cut into carpet, wood floor, or concrete!

The legs, with adjusters for perfect leveling on older floors, are located at the foot of the bed, and extend to lock automatically when the bed is opened for use and they automatically fold away when the bed is raised. The legs also feature rubber feet to protect the flooring.

It is a proven and rugged unit offering the same reliability as all our products, and easy to install. Local mattress support panels are needed, and provide a solid base especially suited to projects and where there is risk of ultra heavy use. We can arrange to supply these if required. THey can be upholstered if preferred to match decor.

One big advantage the Murphy design offers is that the mattress support panel can be adjusted in size to cater for odd, non standard mattress dimensions. This means you don't always have to buy a new mattress....

As preferences shift to slat support systems, the NeXT bed does offer additional comfort and features, and appearance, and has no need for support panels. But there is still a place for Murphy in traditional form, where simplicity of design or lwer cost is important.

If you would like a new colour, we will be pleased to help. We just added anthracite which uplifts the look very nicely. Please ask for a white one too or special features for projects needing large numbers.

The main features are:

GENERAL

- High-quality steel construction - powder-coated in a scratch-proof, black ridge finish.

- The counterbalance extension springs are made of high tensile alloy steel similar to our other designs and made specially for us

- The number of springs may be increased or decreased depending on the weight of the mattress and other bedding. Sufficient springs are provided to balance heavier mattresses.

- The assembly may be attached to the floor or baseboard (skirting board) using our new wall-mount bracket - no need to cut into carpet, wooded floors, or concrete!

- The legs located at the foot of the bed extend and lock automatically when the bed is in use. The legs automatically fold away when the bed is raised. The legs feature rubber feet to protect the floor and are adjustable for uneven floors.

- A nylon webbing strap holds the mattress in position at all times.

MATTRESS FOUNDATION

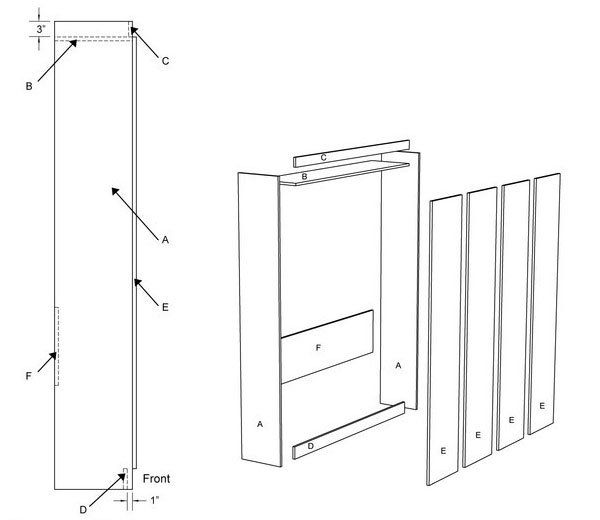

- The mattress is supported by a three-piece base using standard materials to create a platform. See below for typical design.

- The mattress foundation attaches to the side rails of the Murphy bed through pre-positioned screw holes in the side rails.

- The mattress selected - up to 300mm (12”) height - is then installed and held in place with the nylon webbing strap provided.

- You may wish to provide your own mattress foundation locally. Some mattress companies offer this product for immediate delivery. Some users also may wish to create their own base using 13mm or 19mm (1/2” or 3/4”) plywood. A cut list for this option is located with the cabinet cut list.

- Note; a big advantage of this system is that you can create platforms to suit special sizes of mattresses where necessary.

3-PIECE PLYWOOD MATTRESS FOUNDATION

- 13mm or 19mm (1/2” or 3/4”) thick. The perimeter edges can be prefinished, edgebanded, or the foundation covered with fabric.

MATTRESS INSTALLATION

Standard mattress sizes:

- Single/twin: 97cm x 190cm (39” x 75”)

- Full/double: 140cm x 190cm (55” x 75”)

- Queen: 150cm x 200cm (60” x 80”)

Mattress thicknesses vary from 15cm to 38cm (6” to 15”) thick.

You may use a mattress with the Murphy bed equipped with the wall bracket MB-WMB, up to 30cm (12”) high, however you may need a deeper cabinet to accommodate this thickness. A 41cm (16”) deep cabinet will accept up to a 250cm (10”) high mattress.

WALL-MOUNTED BRACKETS

A Murphy bed wall-mount bracket is the adaptor that attaches the Murphy bed mechanism to the baseboard (skirting board). The bracket (MB-WMB) is slotted so the user has flexibility in the thickness of the mattress and the depth of the cabinet.

MURPHY BED BI-FOLD DOOR CABINET CUT LIST

All dimensions are unfinished sizes.

All dimensions units are in inches.

All material is 19mm (3/4 inch) thickness.

Email for metric dimensions if not shown.

Cabinet dimensions can be altered to suit your final design. The Murphy wall bed does not have contact withe the cabinet so materials chosen can be lighter and thinner than with other types of wall bed. Cabinets always need to be fixed to the wall securely, as for any other type of tall cabinet design.

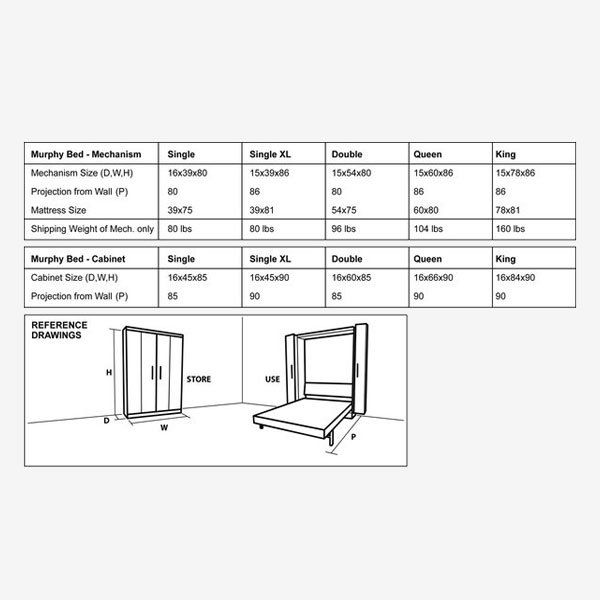

Footprint dimensions

Cabinet size and projection from wall

All dimensions are in inches.

All beds accept mattress thickness up to 30cm(12" )

A US King size unit can be created using a pair of 90cm x 190cm single Murphy beds and adding an oversized top panel of adequate side support to extend the oveall size to 180cm x 200cm or larger, using 25mm or similar strength plywood or equivalent. This will increase projection into your room. Frames should be connected using a central wood batten between adjacent frames at the centre, and bolts to connect the frames securely, locally, so the units are firmly connected.

Are you a furniture retailer looking for an innovative product that will meet your customers changing needs in challenging times?

Since April 2020, demand for creating space at home has surged. Demand for our products continues to grow globally, and we are developing more and more solutions to help the balance of work and rest in the home. This can be created in retail environments and generates high levels of interest and footfall.

For more details and ideas on how we can help, please contact us.

If you would like to distribute or add wall beds to your current range of products, please click here to learn more

To enquire about our Murphy beds, send an enquiry today:

message

We will get back to you as soon as possible

Please try again later

Registered Company Name: WALLBED SYSTEMS LTD

Registered Address: 132 NORFOLK HOUSE, HIGHLANDS HEATH PORTSMOUTH ROAD PUTNEY HEATH LONDON SW15 3TZ

Registered Company Number: 06864129